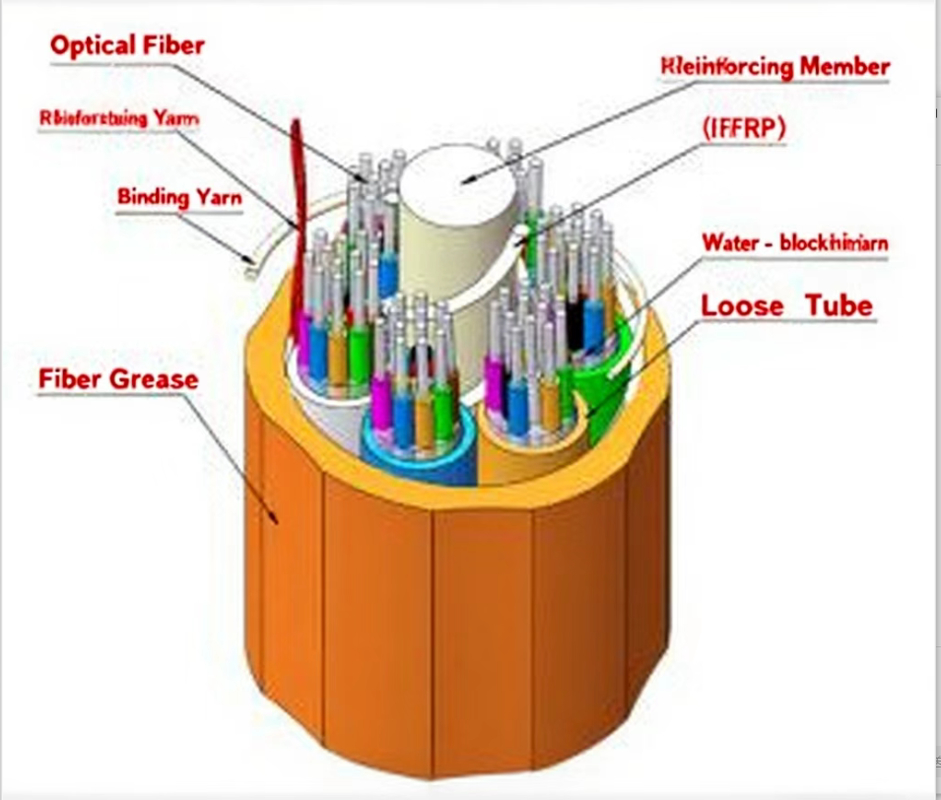

⫸ Product Description: [Non metallic reinforcement component, loose sleeve layer twisted semi dry filling, nylon sheathed communication outdoor air blown optical cable] The structure of the optical cable is to embed single-mode or multi-mode optical fibers into a high modulus plastic filled waterproof compound loose sleeve. The center of the cable core is a non-metallic reinforcement component. For some fiber optic cables with a certain number of cores, the metal center reinforcement component is extruded with a layer of polyethylene cushion layer, and the loose sleeve (and filling rope) is twisted around the center reinforcement component to form a compact and round cable core. Waterproof yarn is placed in the gaps inside the cable core, and nylon sheath is extruded to form the cable.

⫸ Laying method: pipeline air blowing laying, etc.

Scope of application: Suitable for long-distance communication and inter office communication, etc.

⫸ Implementation standard: YD/T 1460.4-2019 Air blown miniature optical cables and fiber units for communication: miniature optical cables.

⫸ Product features: ① Reasonable design and precise control of the remaining length and cabling method of the optical fiber in the loose tube, making the optical cable have excellent mechanical and environmental performance; ② Structural optimization design with optimal fiber capacity; ③ Semi dry cable core water blocking, low-carbon and environmentally friendly; ④ The surface of the sheath has a textured design that can serve as an airflow channel to enhance its blowing performance; ⑤ The protective sheath is made of nylon, which has high hardness and wear resistance; ⑥ Lightweight, small outer diameter, excellent bending performance, and a designed lifespan of over 25 years for optical cables.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!